Bowes Fastrac Limited

Turning ideas into reality for many years

Welcome

We specialise in translating ideas into 3D reality from concept to production. This can be for a variety of applications including sales and marketing presentations, design sign off, testing and evaluation. We provide an enviable range of services and expertise covering a wide spectrum of markets and industries with specialisation in Automotive and Aerospace sectors. The extensive knowledge and experience of our people is supported by an impressive array of CNC machines, boasting one of the largest 5 axis capacities in the UK. This, coupled with a strong CAD/CAM team and skilled pattern shop, enables Bowes Fastrac to realise your design and development projects, no matter how complex. Whatever your project, however large or small, Bowes Fastrac can help turn your idea into reality.

aerospace

automotive

marine

motorsport

engineering

introduction

Bowes Fastrac specialises in turning ideas into reality from concept to production. This can be for a variety of applications including sales and marketing presentations, design sign off, testing and evaluation. We provide a comprehensive range of services and expertise covering a wide range of markets and industries with specialisation in the Automotive and Aerospace sectors. The extensive knowledge and experience of our people is supported by a comprehensive array of CNC machines varying in size and capability. This, coupled with a strong CAD/CAM team and fully skilled pattern shop enables Bowes Fastrac to realise your design and development projects no matter how complex. Whatever your project, however large or small, Bowes Fastrac can help turn your idea into reality. We also undertake the design and manufacture of patterns, tooling, jigs and fixtures in a variety of materials, finishes and a variety of applications. Please feel assured that all of your enquiries and projects are handled with the utmost confidentiality at all times along with total security.

Mock-ups & prototypes

Production

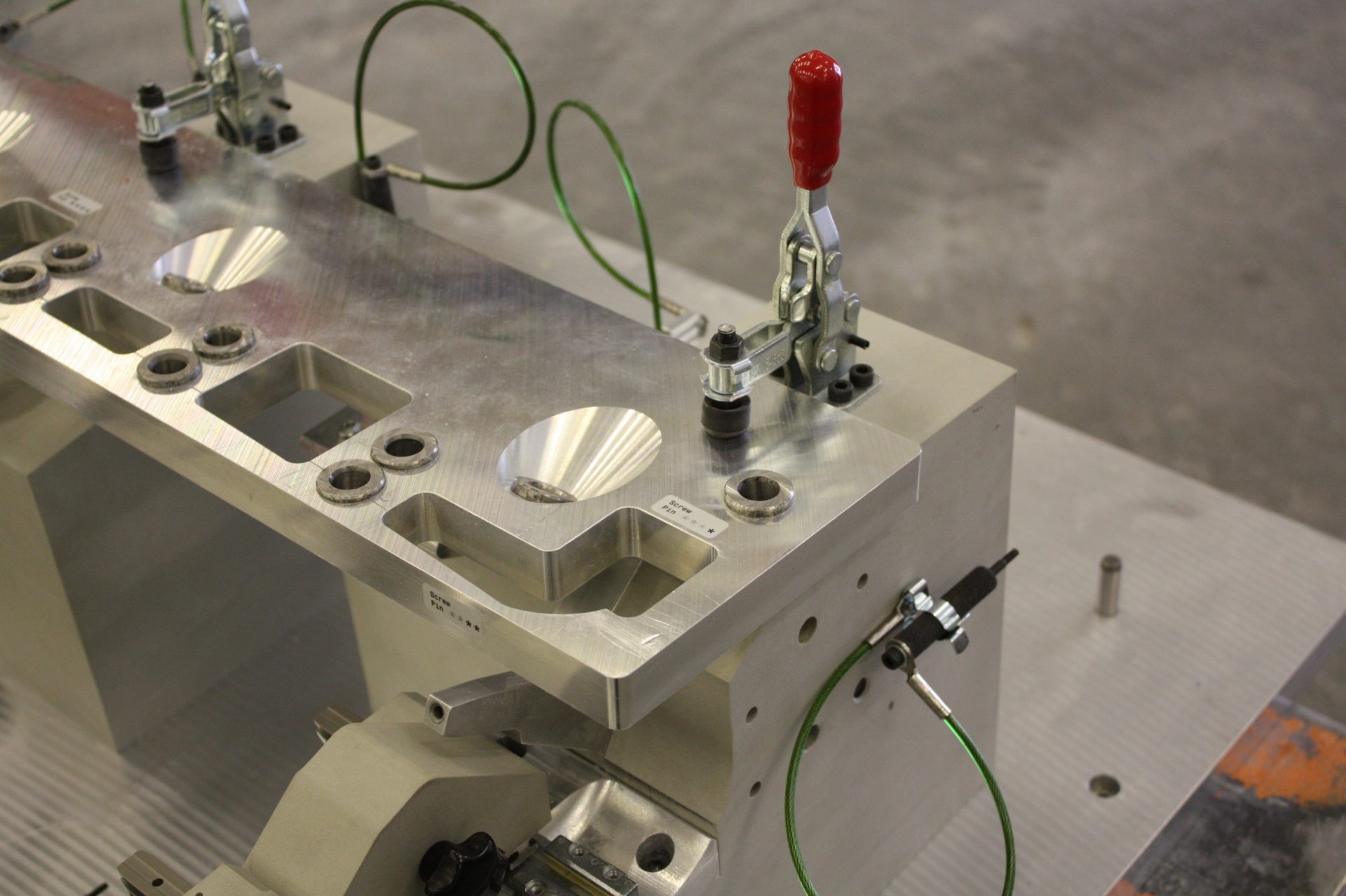

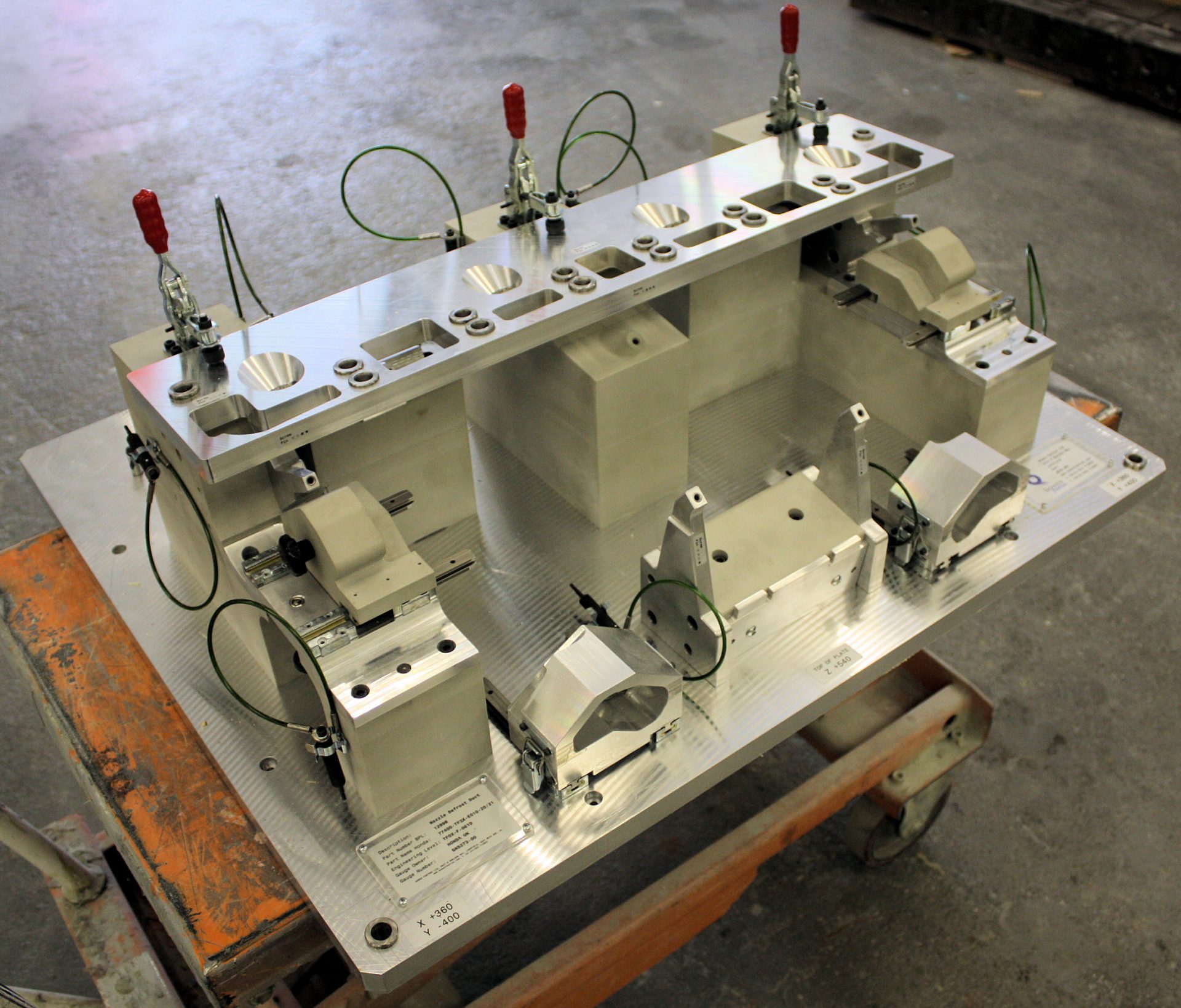

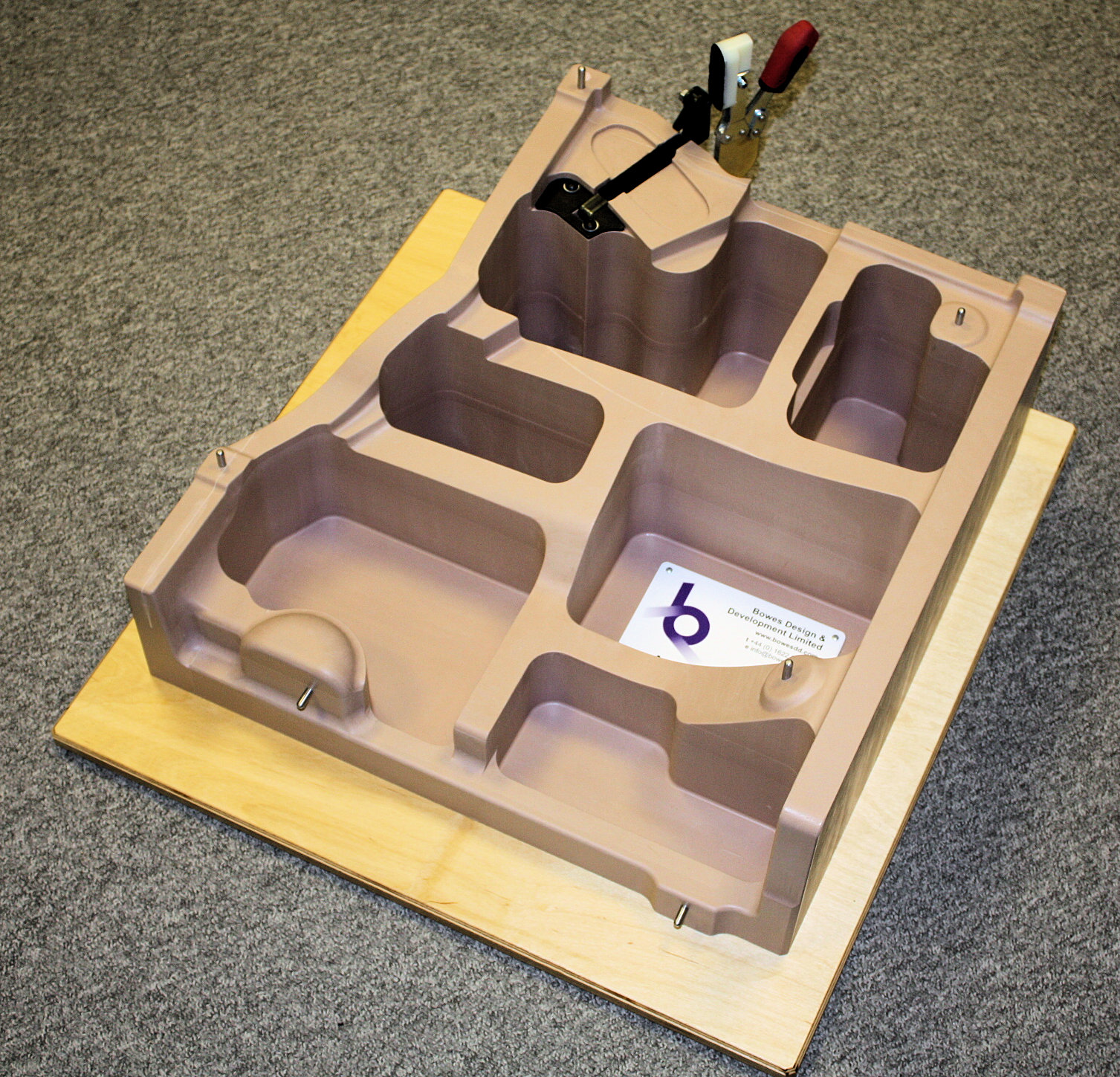

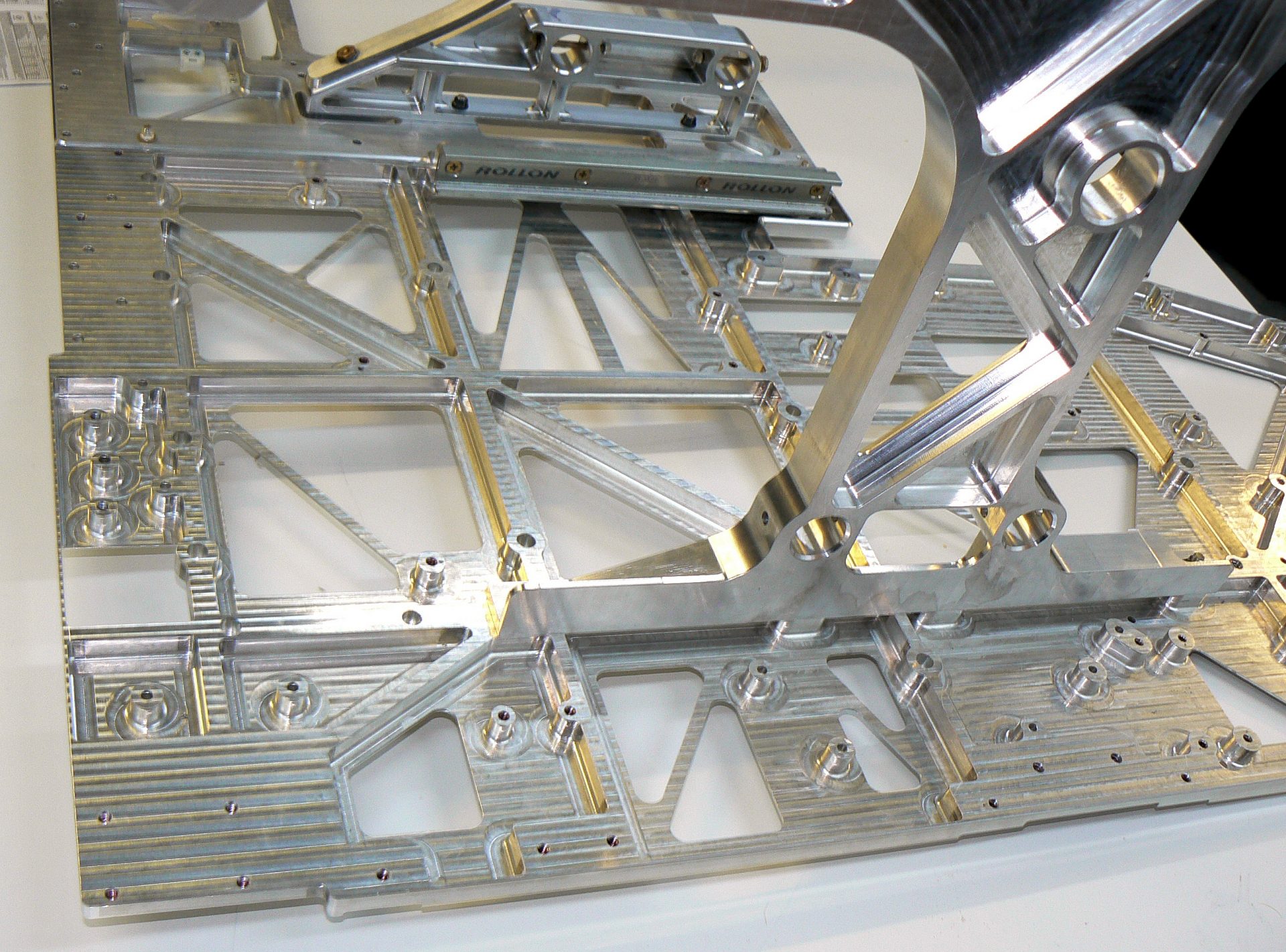

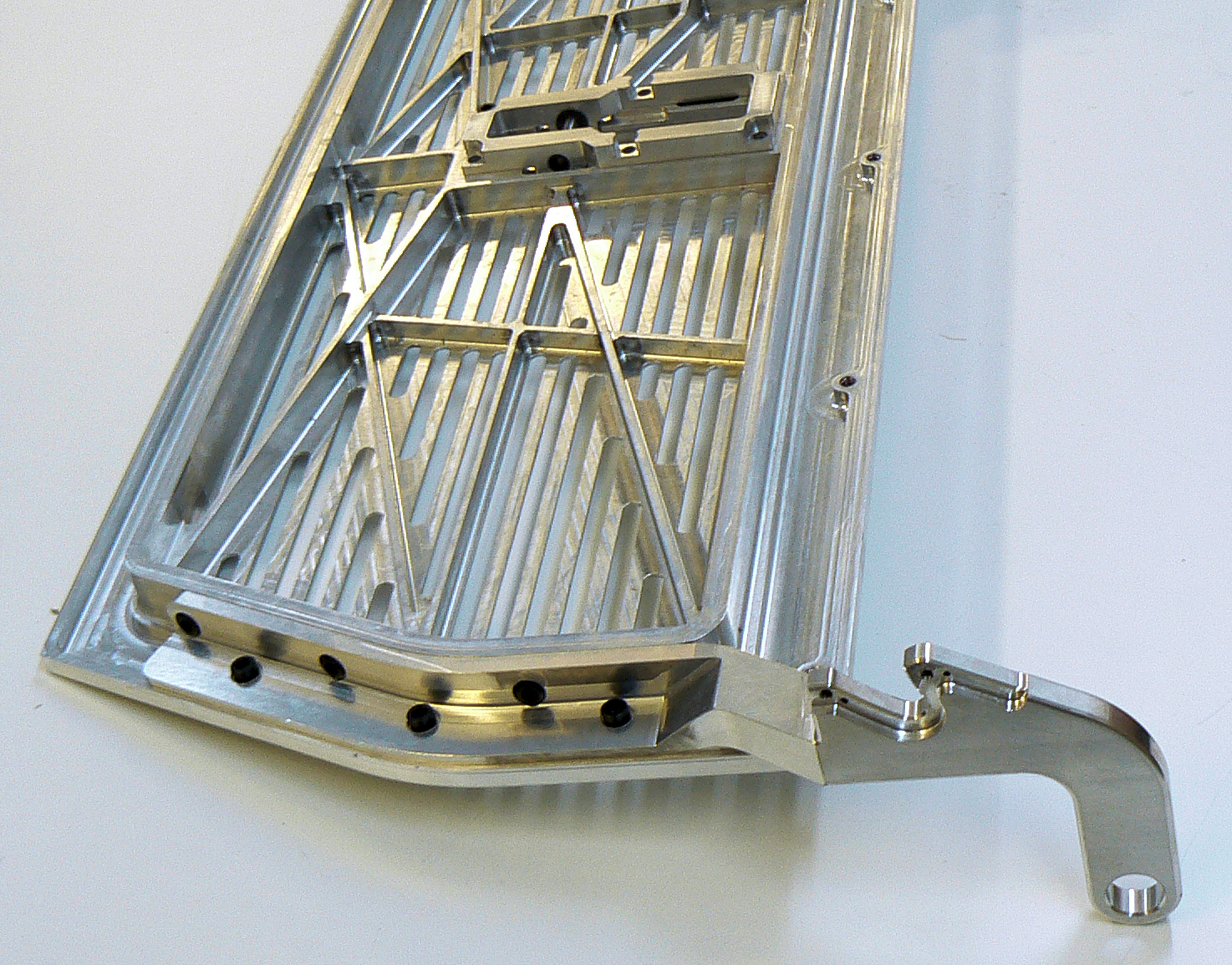

Jigs, fixtures & tooling

CAD & design service

back to the top

Aerospace

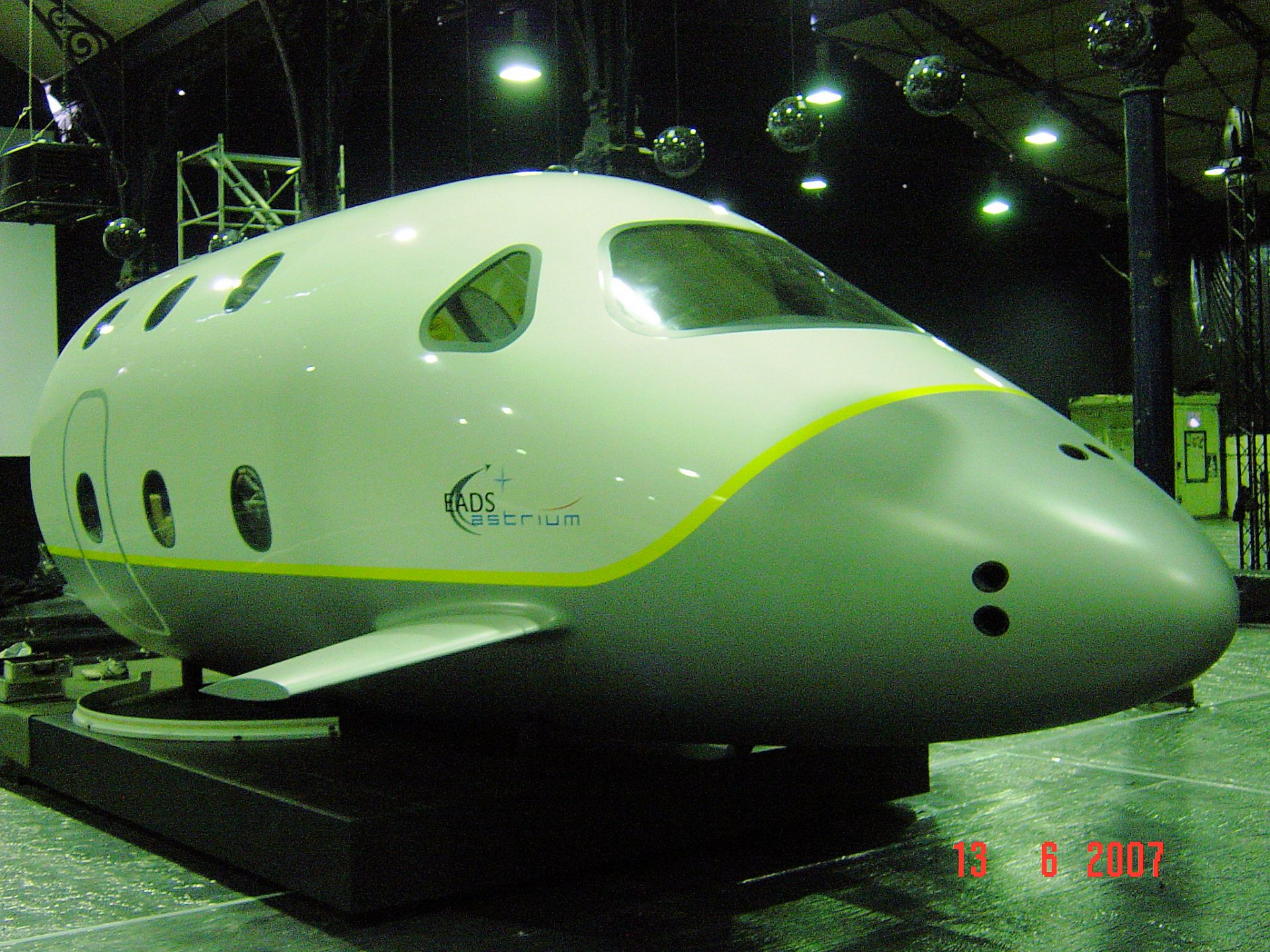

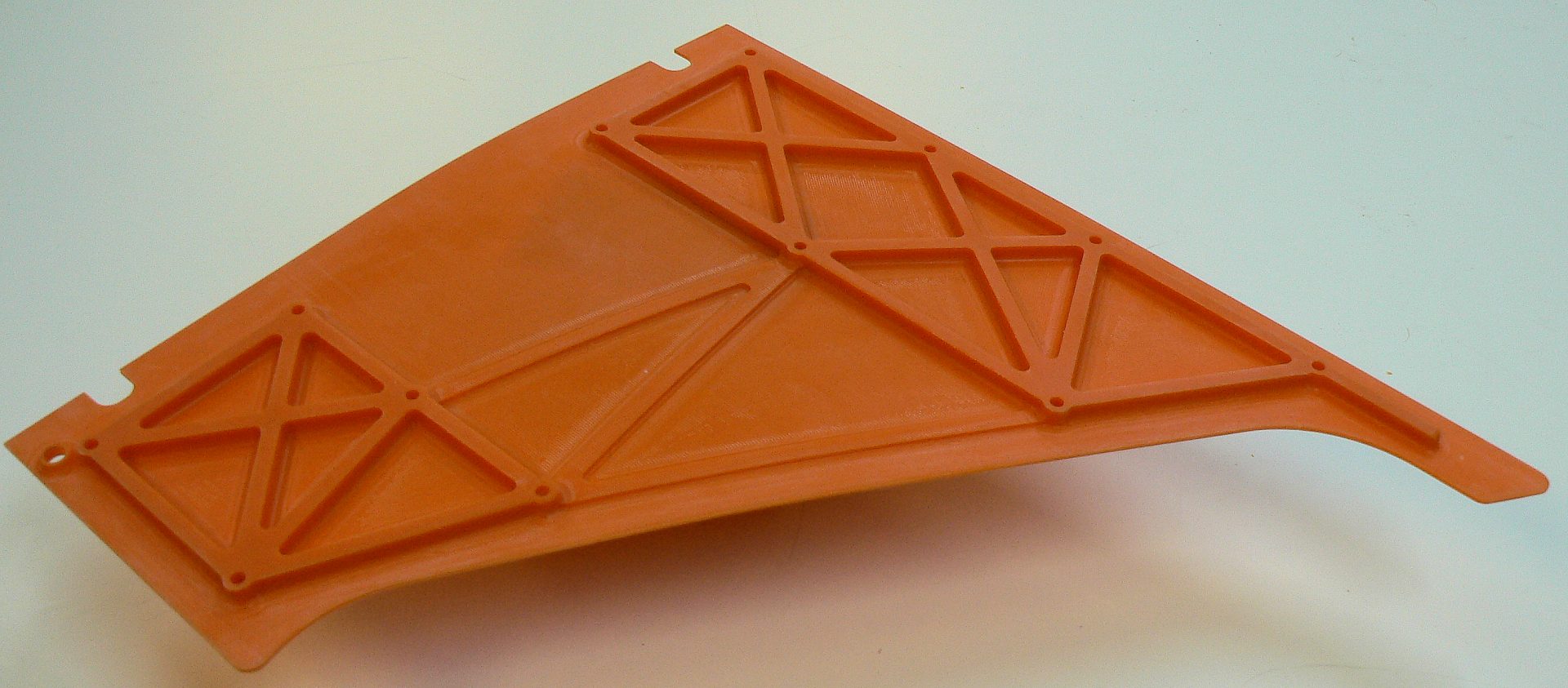

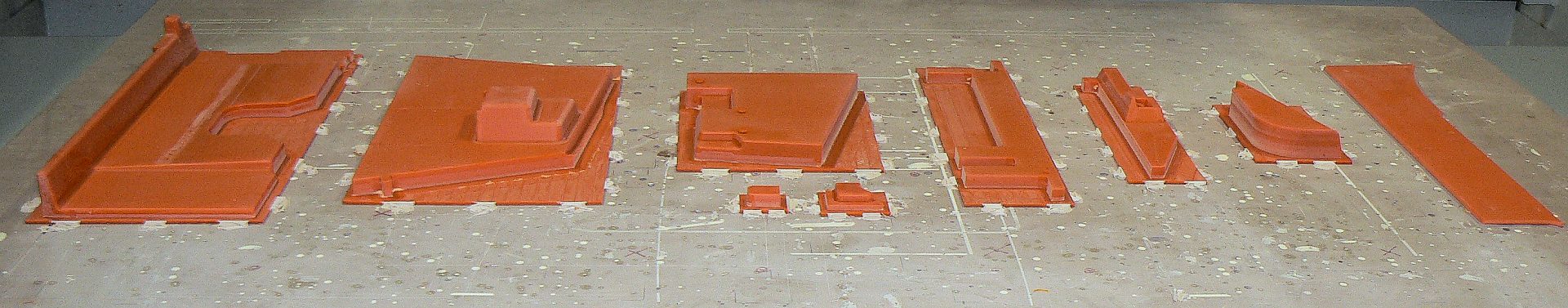

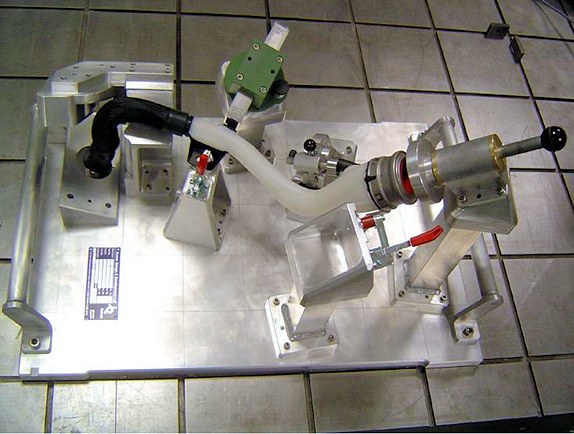

Bowes Fastrac is a leading world class supplier to aerospace OEM’s and airlines for design mock-ups, tooling, jigs & fixtures including parts. We are renowned for delivering high quality products in increasingly short timescales. Bowes has an impressive track record in both Europe and the USA for delivering a vast array of fully functioning mock-up cabin interiors from 'blue sky' concepts to cabin environment test rigs for engineering evaluation. No project is too big or too small from the smallest component to fully fitted out cabin interior with a full complement of seats, cabin linings and monuments. By combining a variety of specialised processes and materials mixed with our unique know how Bowes can create mock-ups at all levels from simple form and volume studies, right up to complex training and development prototypes in non and aircraft spec materials.

back to the top

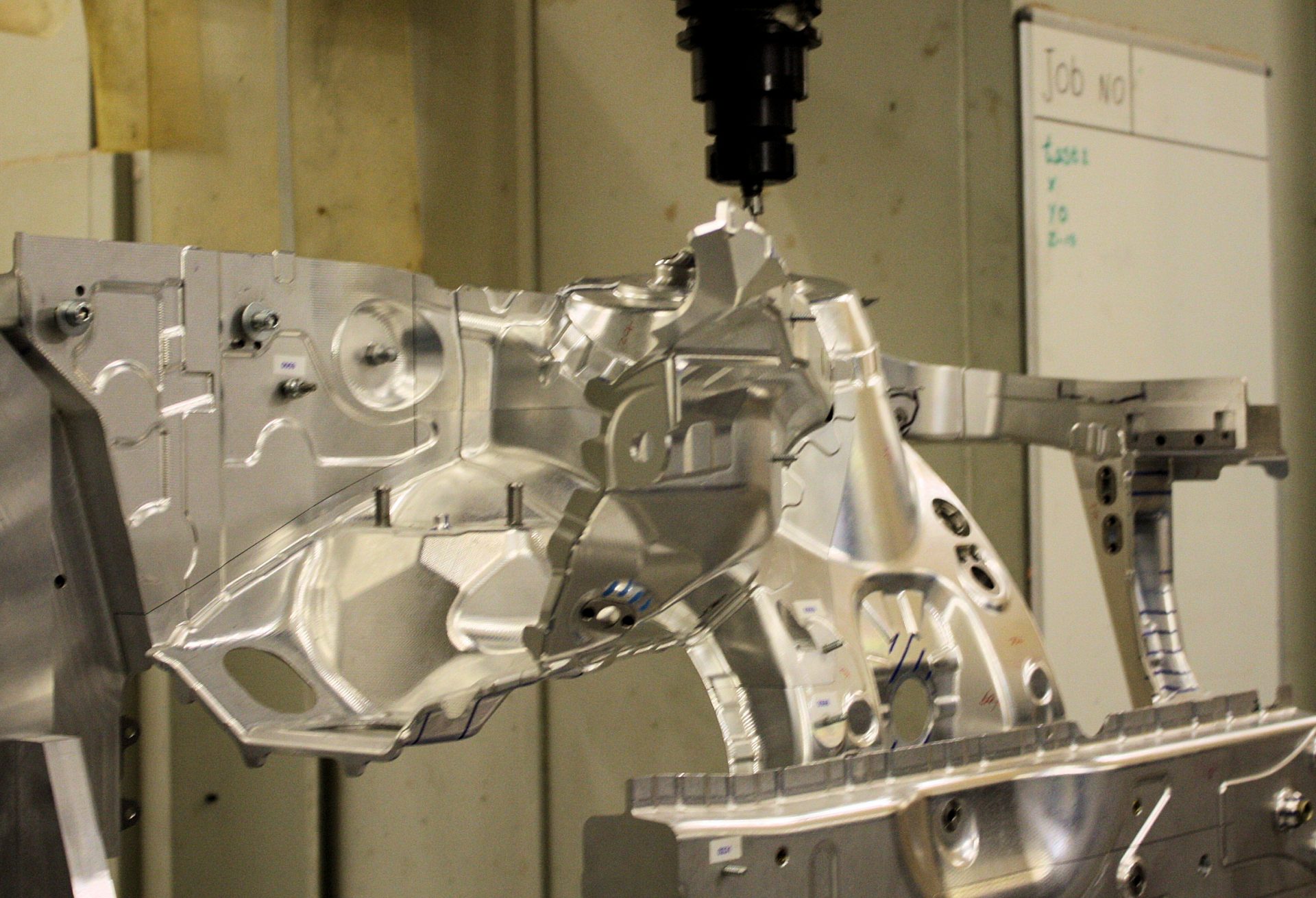

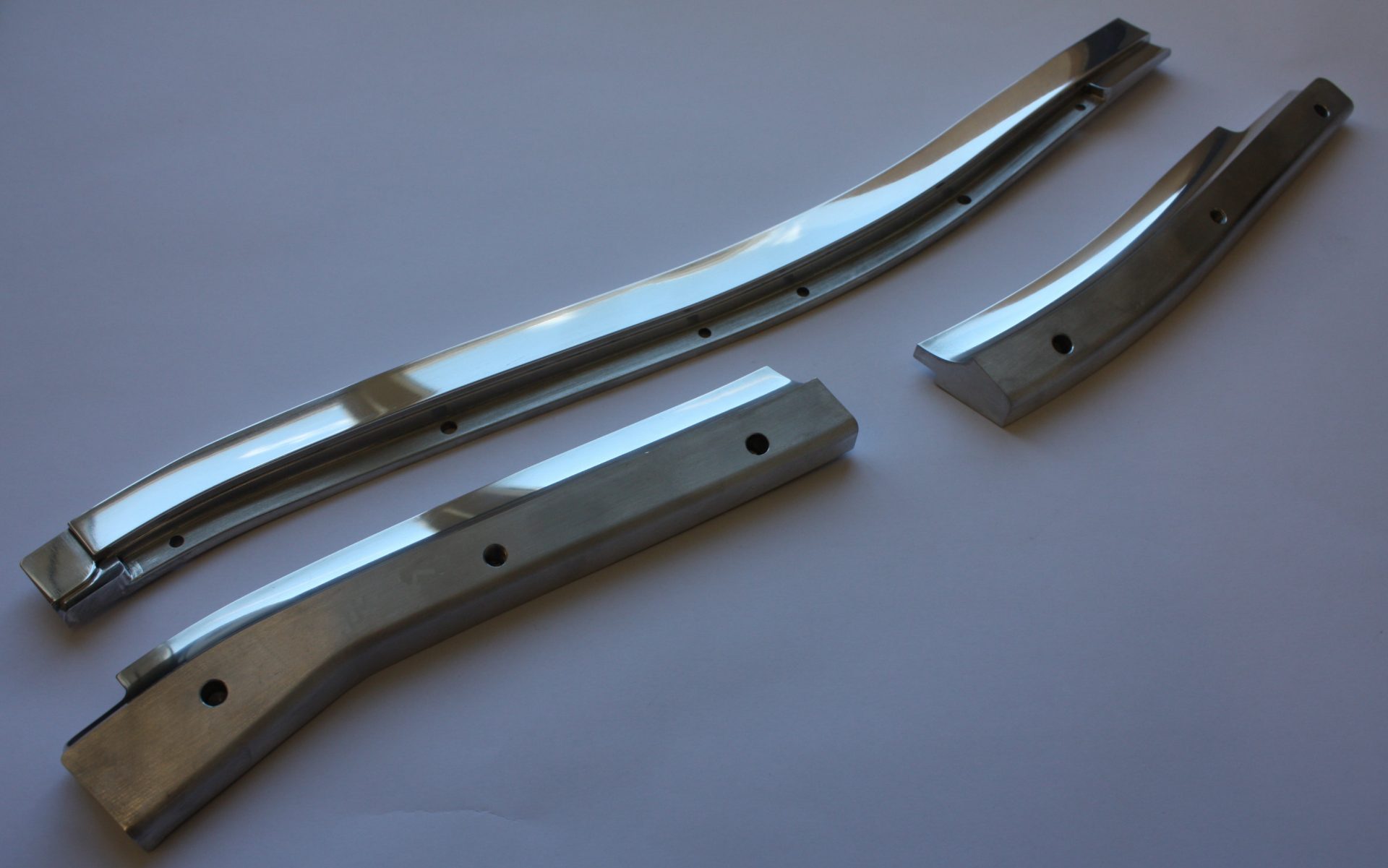

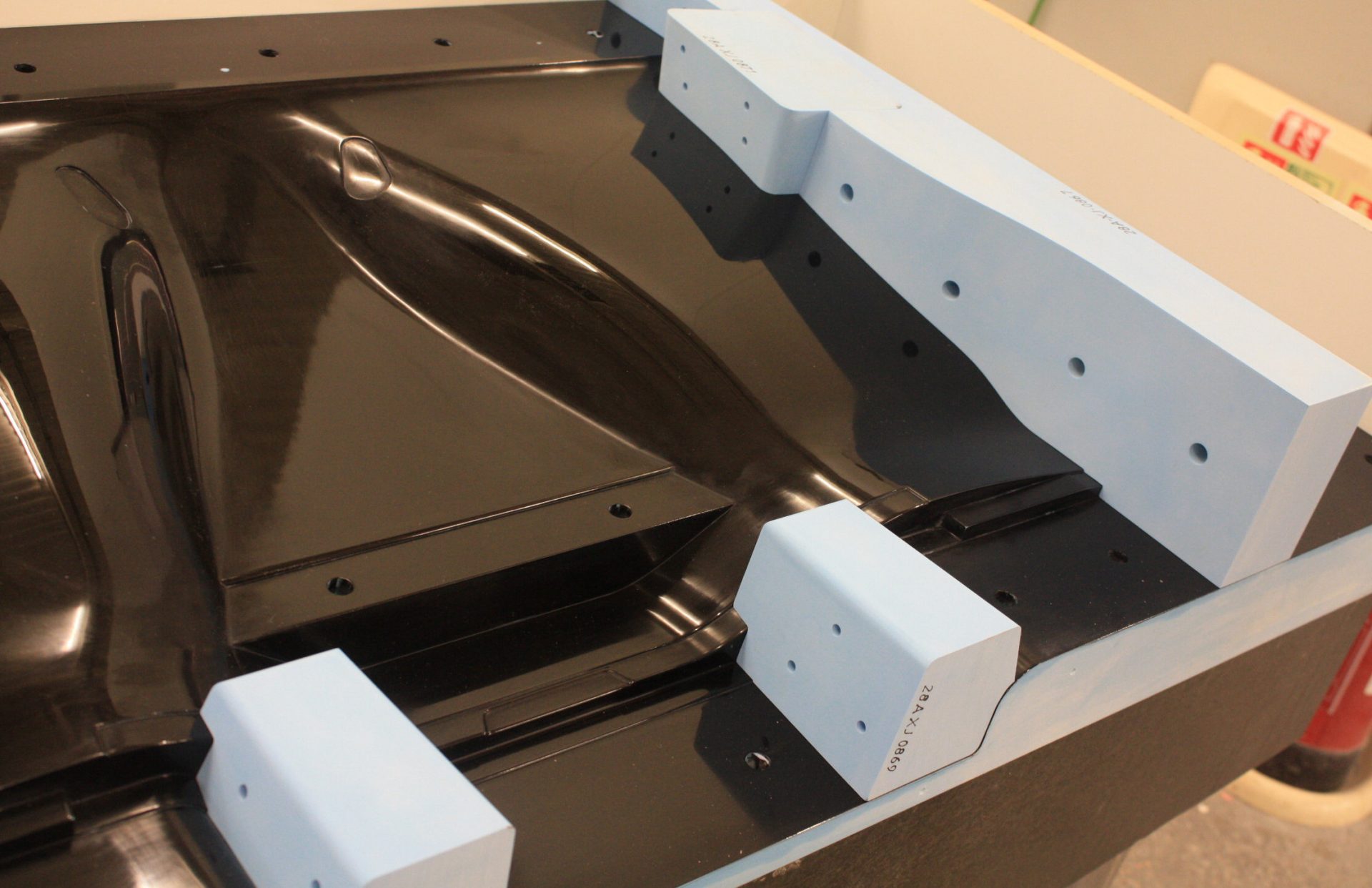

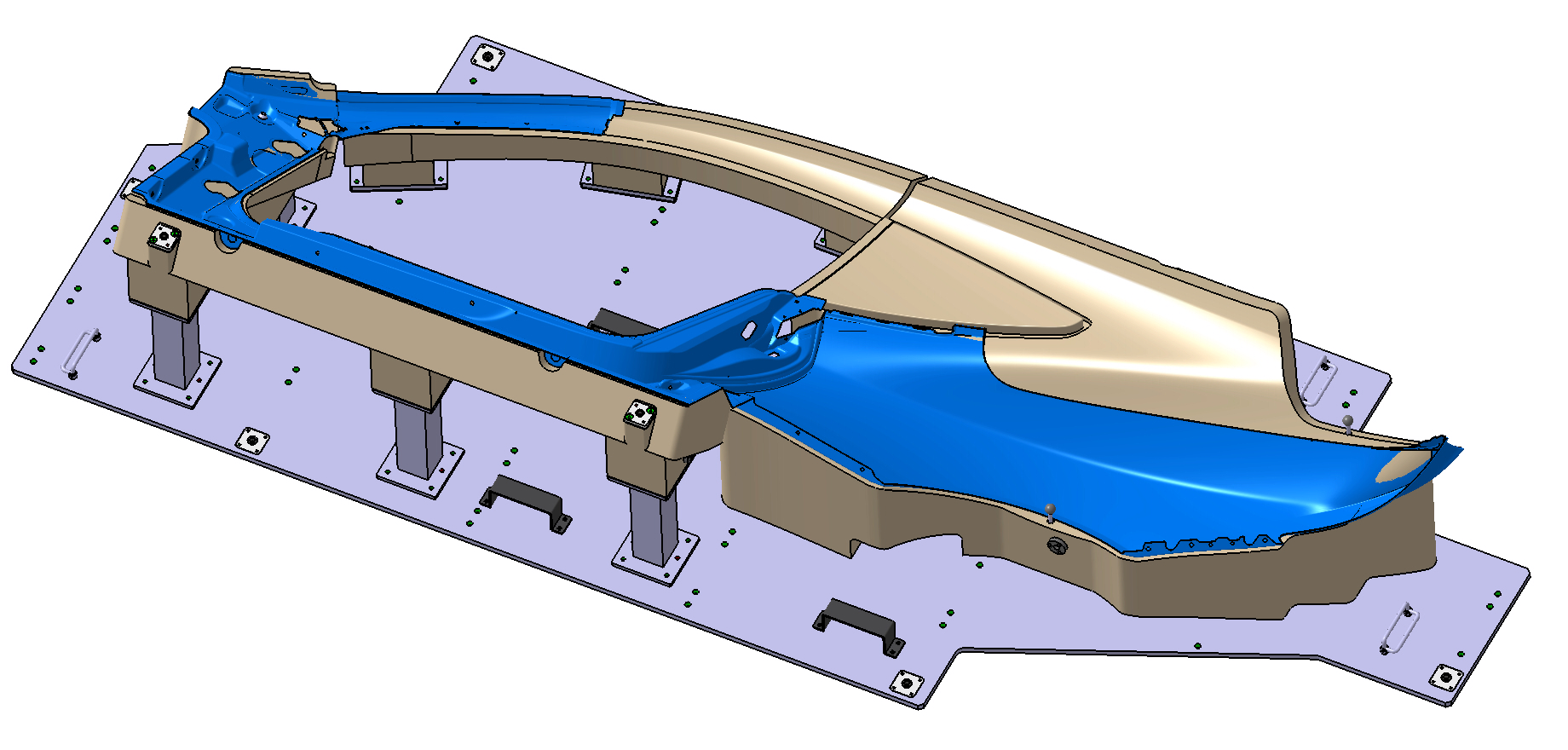

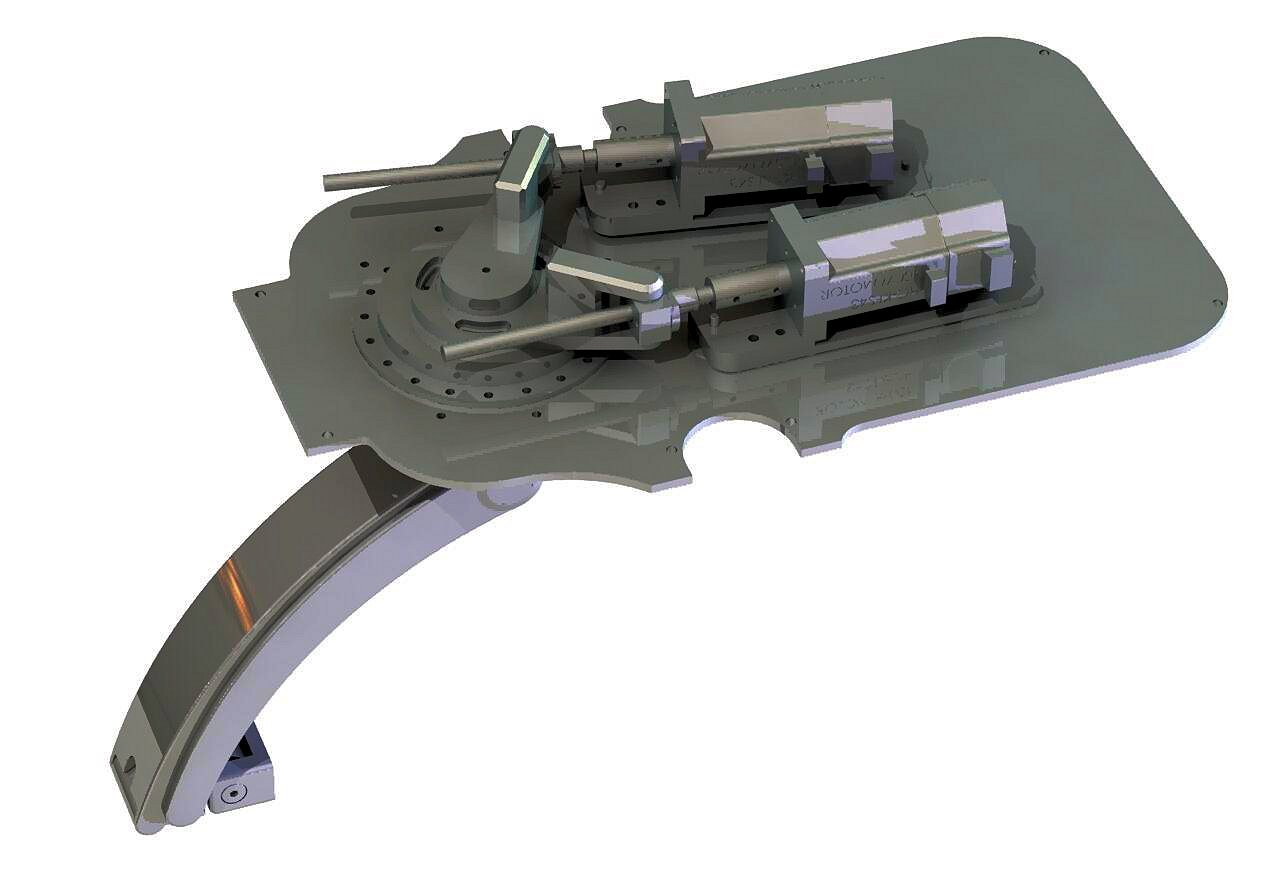

Automotive

Our in-house experience and manufacturing capability have given Bowes Fastrac a strong reputation in the automotive sector. From the smallest component to a full size car, we have the capability to deliver to the tightest of deadlines. Our customers include the worlds most renowned OEMs to whom we have successfully delivered show vehicles, environment cubes, production tooling, jigs, fixtures along with a variety of data prove out models, mock-ups and prototypes. We have also successfully completed a number of short production runs of highly specialised composite parts for road cars. In short, whatever your requirement, we have the know how and ability to meet your needs.

back to the top

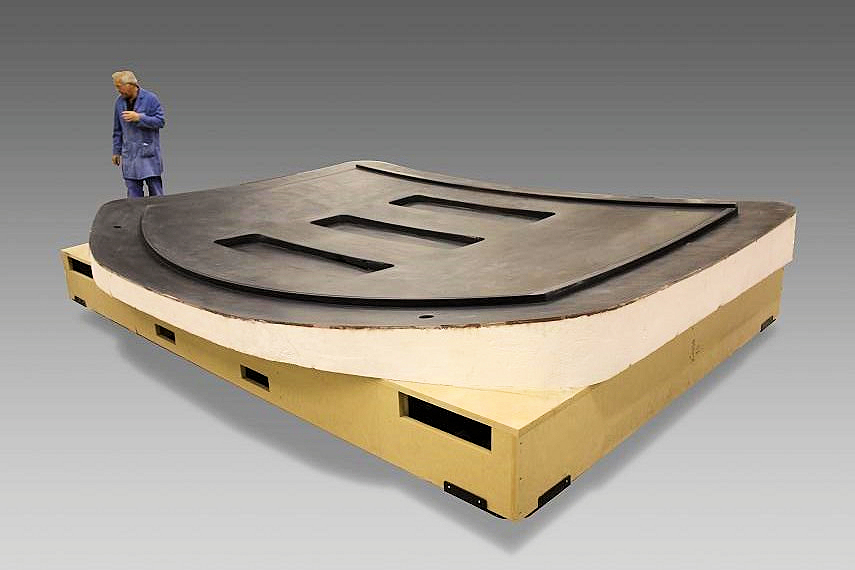

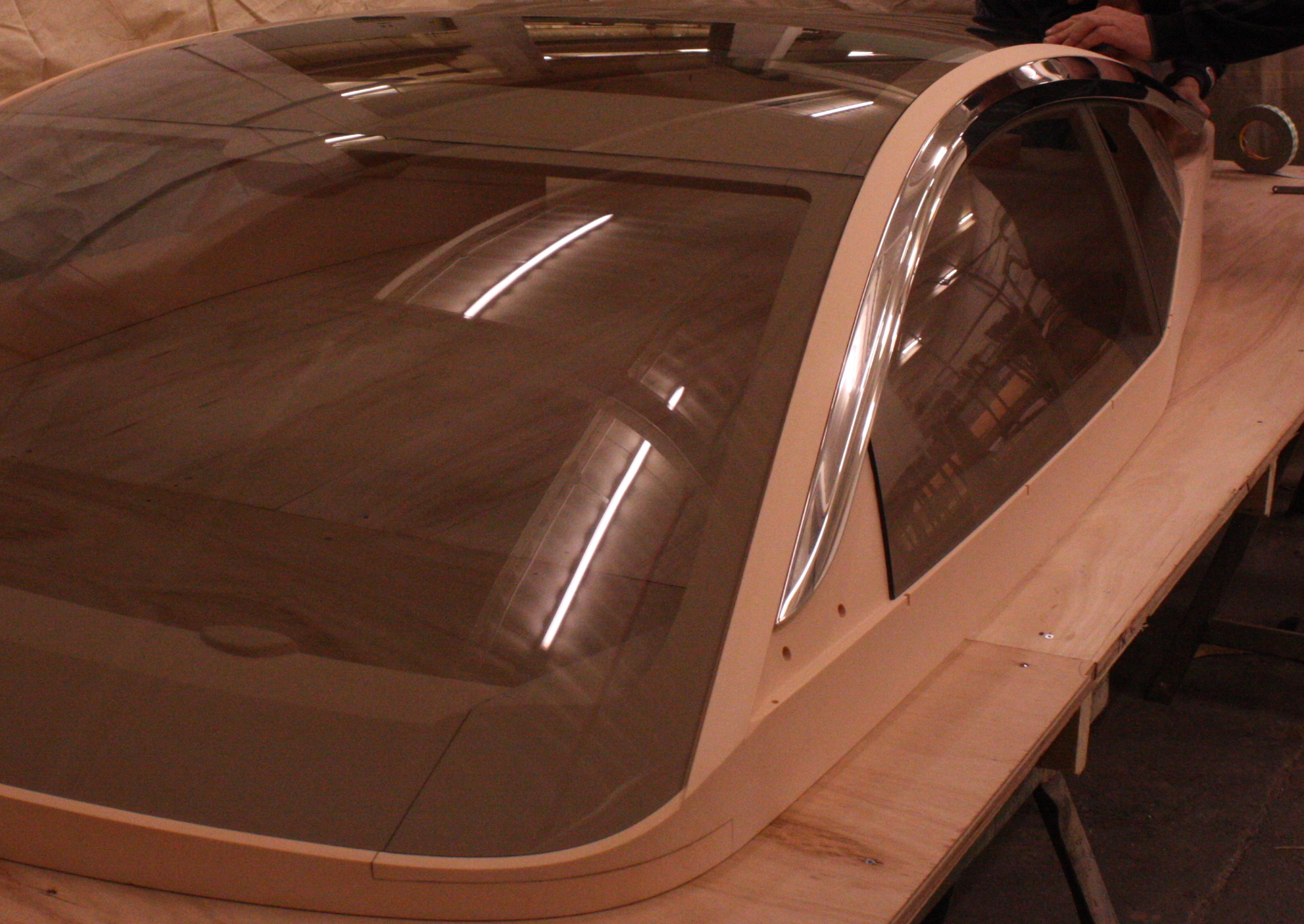

Marine

Our capacity to manufacture extremely accurate, large scale patterns and tooling is allowing us to establish a growing reputation in the marine sector. Our recent investment in the latest paste technology enables us to produce highly cost effective, large patterns suitable to manufacture GRP production tooling. Attention to detail and exacting standards ensures a high gloss finish, thus reducing finishing time and production costs. No matter how big or complex your project, Bowes can offer a cost effective solution to ensure quality, consistent parts every time.

back to the top

Motorsport

We have over the years been proud to supply several of the grids most successful motorsport teams. Our impressive CNC capability and rapid turnaround means that we can support the most aggressive of development schedules to the highest precision. The highly confidential nature of this work means that we are limited to what we can show, so please call to discuss your requirements in detail

back to the top

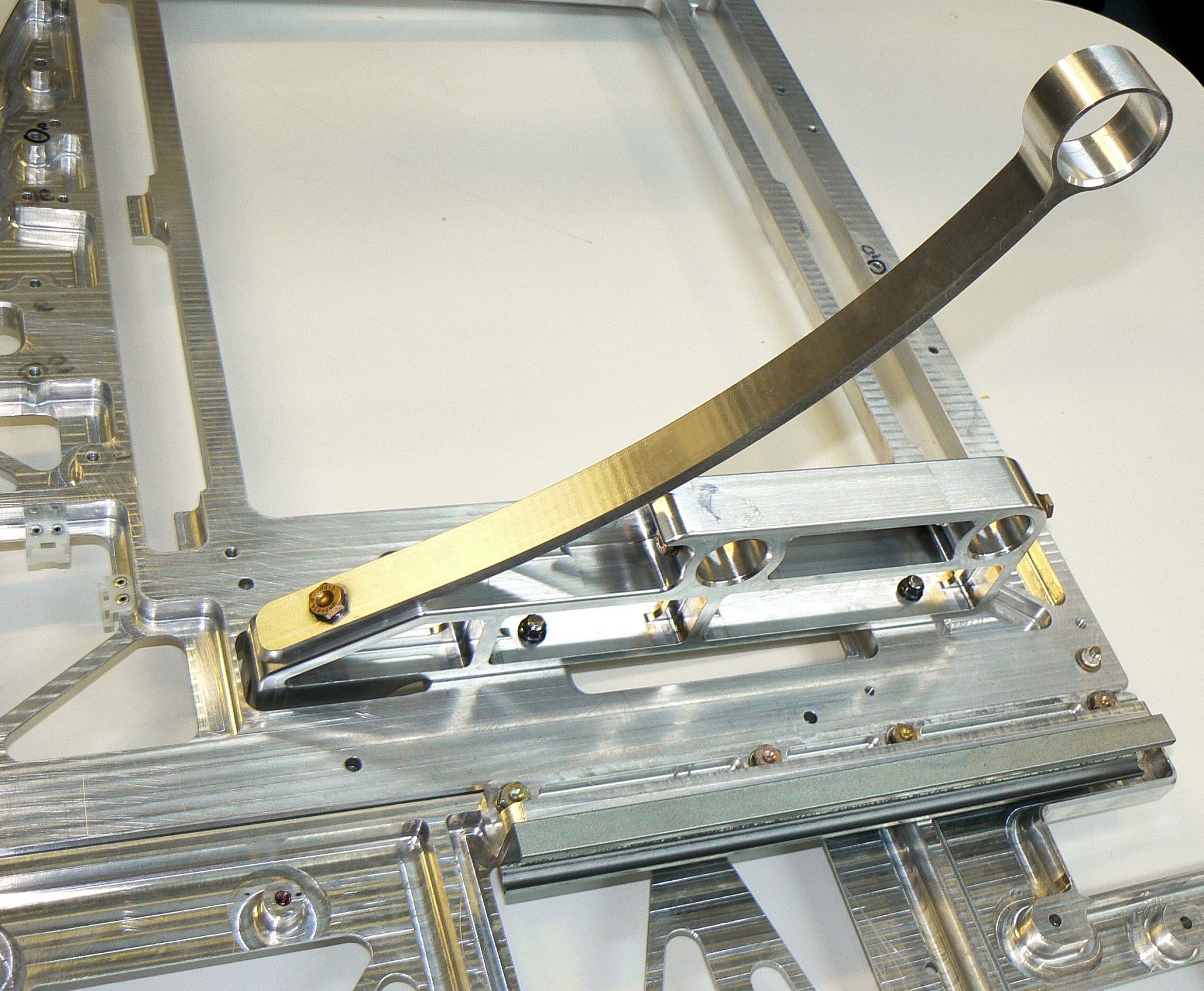

Engineering – Standard & Bespoke

In addition to our core disciplines, we also undertake projects from other market sectors. Our wealth of experience and in-house knowledge base allows us to transfer ideas and technologies to offer solutions to a large variety of challenges. In particular, our expertise in composite parts manufacture can offer a solution where traditional materials and processes just can’t deliver. If you have a challenging manufacturing problem give us a call to see how we can help as we also undertake bespoke design engineering for more specialist applications where a unique element or module is required that falls out of the remit of an OEM ‘s standard design giving the owner an exclusivity that is not in a standard product.

back to the top

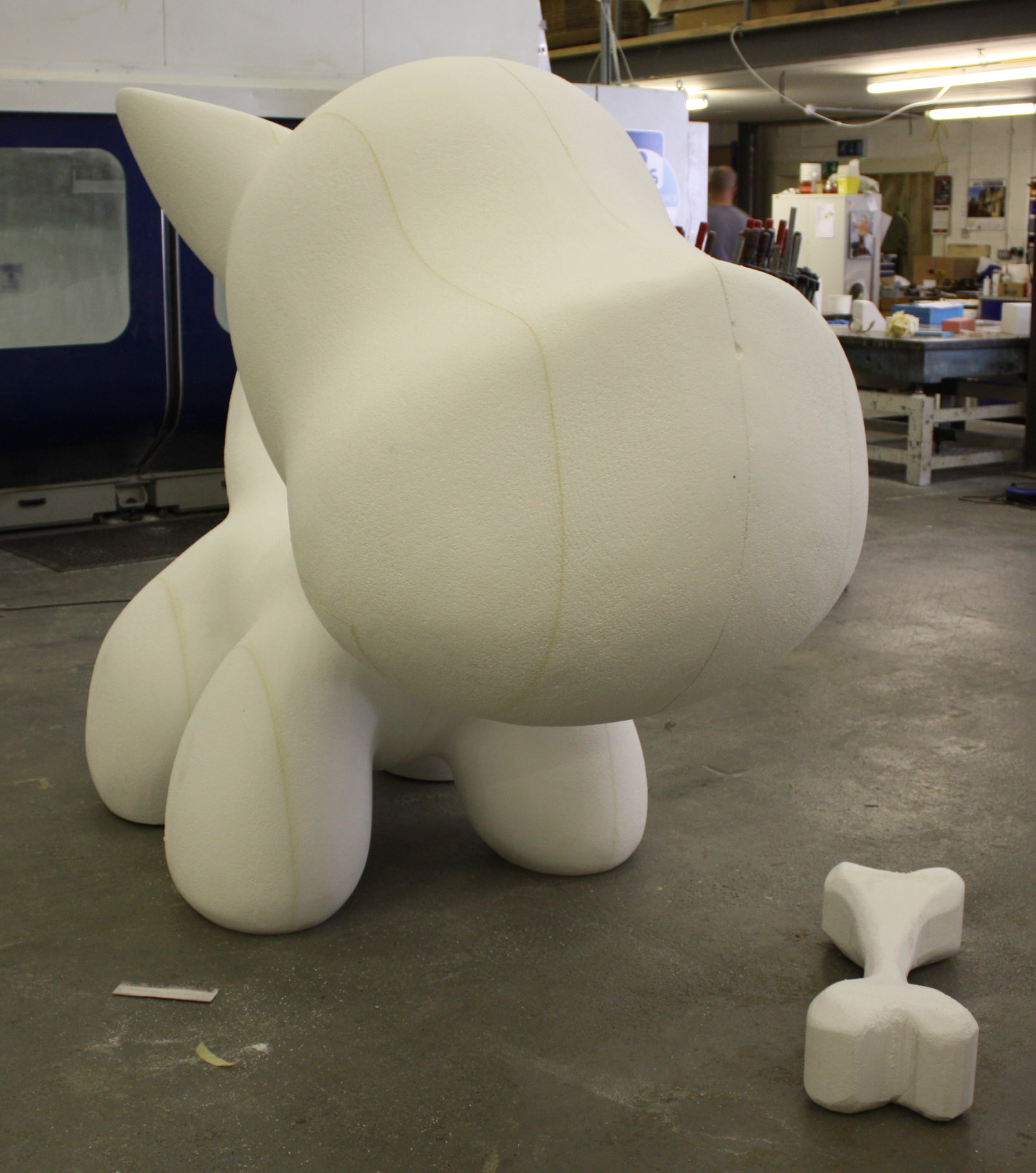

TV & Film

We undertake the design and build of film sets, sculptures, exhibition stands, to include GRP parts, Props, scale models, acrylic drape forming and polishing.

back to the top

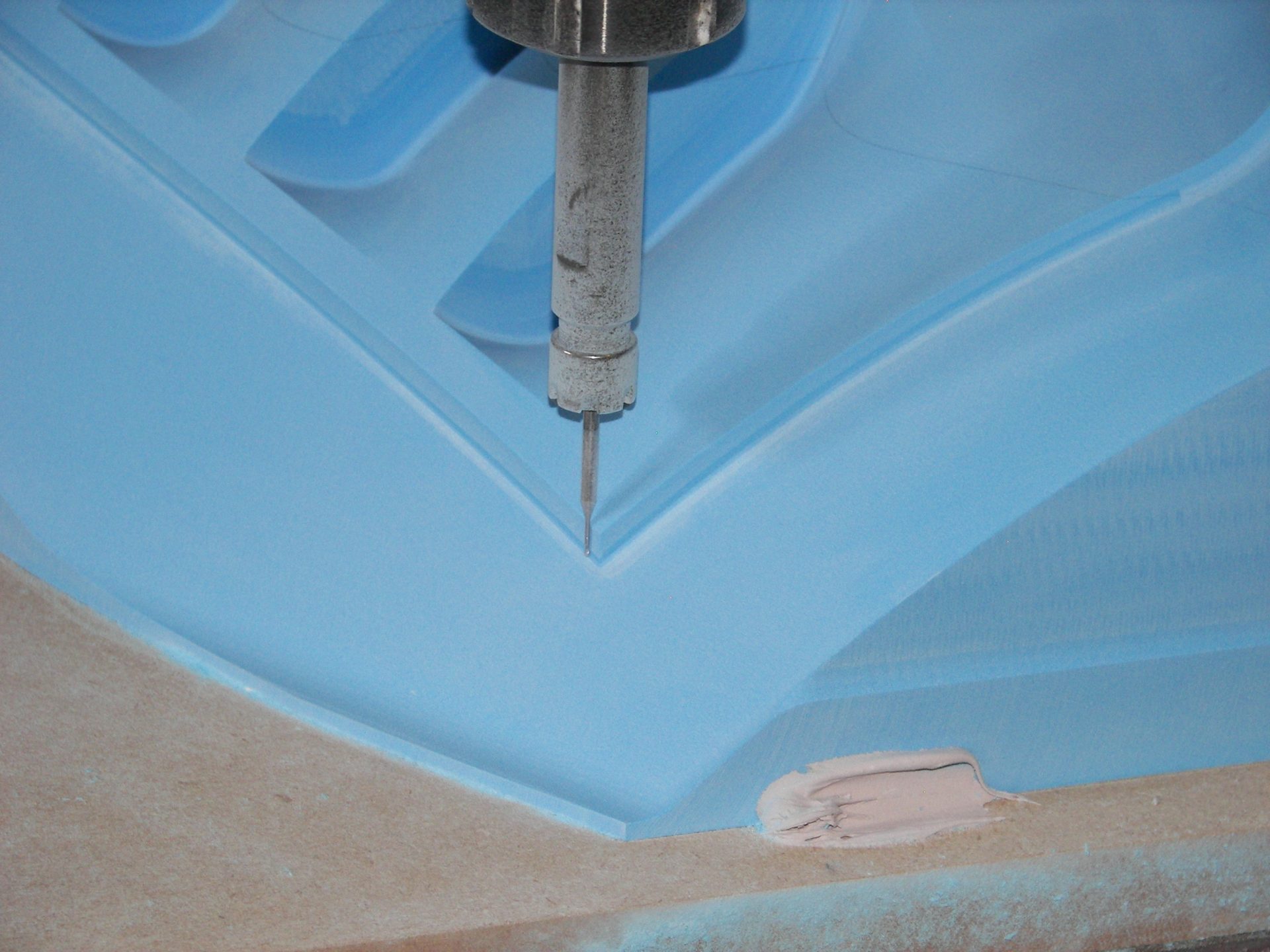

Services

Turning concept into reality takes design flair, production capability and the right tools for the job. Bowes Fastrac has invested heavily in the means to manufacture the necessary moulds, tools and fabrication to deliver the final product. With a diverse range of three and five axis machining centres, Bowes Fastrac Ltd has the

capability of producing some of the largest profile, one piece tools in the country, providing precision and speed of turnaround to support the most demanding production schedule. Fully supported by Computer Aided Design and Manufacture (CAD/CAM) we can take basic, two and three dimensional CAD data and develop that into complex three dimensional surfaces for tooling and components. We are ISO9001 compliant supported with CMM inspection

Mock-ups & Prototyping

Rapid 1:1 Visualisation models

Show Vehicles

Body & Trim Details

Machined scale models

Wind Tunnel Models

Data prove out models

Environment cubes

Body in white mock-ups

Full cabin interiors

Working protoypes

Design development

CAD/CAM service

Process

CNC machining

Pattern shop fabrication

Carbon, phenolic parts

GRP (drape, vacuum, RTM)

Resin transfer moulding

Resin Injection moulding

PU moulding (RIM)

Vacuum casting

Composite tooling

Composite part manufacture

Paintshop

CMM & Faro arm inspection

Machining capability

CMS Aries – 5 axis – 2600 x 1500 x 1200mm

Correa 1 – 5 axis – 3500 x 3000 x 1200mm

Correa 2 – 5 axis – 2500 x 2500 x 1300mm

Rye 1 – 3 axis – 2438 x 1524 x 762mm

Rye 2 – 5 axis – 2405 x 1400 x 575mm

DMU – 5 axis – 800 x 800 x 700mm

Bridgeport 1 – 3 axis – 1000 x 500 x 500mm

Bridgeport 2 – 3 axis – 1005 x 604 x 550mm

Bridgeport 3 – 3 axis – 1005 x 604 x 550mm

Haas – 5 axis – 1625 x 812 x 720mm

Dugard – 5 axis – 1025 x 512 x 550mm

CMS Aries – 5 axis – 2600 x 1500 x 1200mm

Correa 1 – 5 axis – 3500 x 3000 x 1200mm

Correa 2 – 5 axis – 2500 x 2500 x 1300mm

Rye 1 – 3 axis – 2438 x 1524 x 762mm

Rye 2 – 5 axis – 2405 x 1400 x 575mm

DMU – 5 axis – 800 x 800 x 700mm

Bridgeport 1 – 3 axis – 1000 x 500 x 500mm

Bridgeport 2 – 3 axis – 1005 x 604 x 550mm

Bridgeport 3 – 3 axis – 1005 x 604 x 550mm

Haas – 5 axis – 1625 x 812 x 720mm

Dugard – 5 axis – 1025 x 512 x 550mm

phone

address

- Bowes Fastrac Ltd

- Unit 8 Sheldon Way

- Larkfield

- Kent

- ME20 6SE